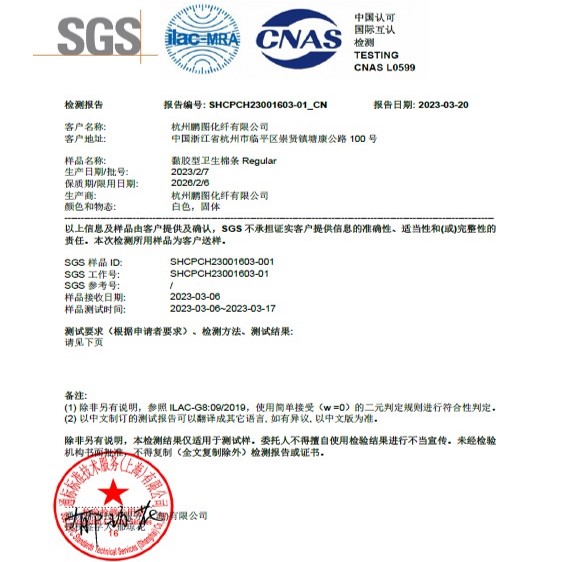

With three pillars of quality system support (leadership, the design and development standards, quality control procedure), and four aspects of quality system operation (materials and products, equipment and technology, production and packaging, laboratory testing), Tianqing quality control has established process validation procedure, change management system, inspection, and rapid error correction mechanism. Tianqing conduce regular staff quality and skills training assessment, to ensure that the quality of products not only in line with national standards, but also in line with the internal quality requirements of Tianqing, to provide consumers with high quality products.

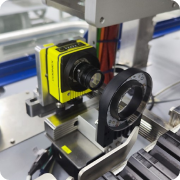

Online process detecting and laboratory testing, the pursuit of product "zero" defects

100% online process detection, a complete closed-loop process of quality defect detection, rejection, recording and analysis.